Our Capabilities

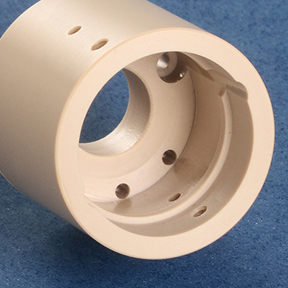

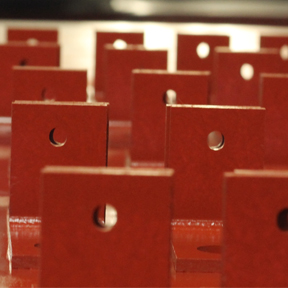

The enormous resources, capabilities, and technologically advanced equipment of Aurora Technologies, Inc. allow us to meet your exacting specifications at the best possible price. And our wide variety of in-stock materials allows us to custom manufacture punched, machined, and vacuum-formed plastic components, often within short time frames. To ensure accuracy and save time, we also can work directly from your electronic CAD files.

WHY CHOOSE AURORA TECHNOLOGIES, INC.?

Aurora Technologies, Inc. is committed to continual improvement in all areas of our organization with customer satisfaction as the company’s main priority: we want to be our customer’s preferred supplier. Utilizing state of the art technology such as 3D model based CMMs or even standard gauges our quality team is committed to ensuring fabrication to your exacting specifications. Every employee of Aurora Technologies, Inc. is charged with the responsibility to produce quality products that achieve the company’s objectives for customer requirements, on-time delivery, and maintaining a safe work environment.

Safety and quality are top priorities at Aurora Technologies, Inc. The organization demonstrates its commitment to these values by earning reputable certifications and facilitating continuing education for personnel. ATI managers are certified with the Occupational Health and Safety Administration (OSHA) 30-Hour Training.

The Safety Manager and maintenance personnel are certified in arc flash training and complete annual refresher courses. Safety Committee members and janitorial staff are certified in the administration of first aid and CPR, the containment of bloodborne pathogens, and the use of fire extinguishers. The Director of Quality Assurance maintains ATI’s registration to ISO:9001 at all seven facilities and to AS9100D at the facilities in Pacific, Missouri. Additionally, ATI participates in the Underwriters Laboratories Inc. Recognized Component Supplier Program for Fabricated Parts.

Aurora Technologies, Inc. aims to exceed all customers’ expectations. Since its inception in 1988, the organization has grown into a team of nearly 200 individuals across 7 facilities in North America. ATI personnel regularly engage in continuing education and practical learning opportunities concerning safety, efficiency, and quality in production. Additionally, they cooperate in a dynamic environment where skill sets and experience are openly shared among colleagues.